TOPICS

|

BOLT

ON HOLDS

The first bolt on

holds for artificial climbing walls were designed or devised by

Leonard C. Anderson in the late 1960's.

Many forms of bolt on holds were developed in the early days. In

the early 1970's Gordon Bendall, before he founded Bendcrete,

experimented with glueing rocks to steel plates with epoxy resin so

they could be bolted or screwed to plywood panelled climbing walls.

It wasn't until 1985 that Francois Savigny invented the bolt on

hold we know it today, and founded Entreprise Climbing Walls.

Many materials have been used over the years to make bolt on holds

from rock, concrete, wood and resins. The most popular and practical

in the climbing wall industry was resin as it set very quickly and

allowed multiple holds to be cast from one mould. Resins used were

polyester, epoxy, polyurethane and acrylic but far the most popular

was polyester resin, it was cheap readily available, and it soon

became any industry standard.

|

Bolt On

Holds

Wikipedia currently has no defintion for 'Bolt on holds' but

defines 'Climbing Holds,' an artificially made hand or foot hold

used on climbing walls to aid a clmbers progress. They are described

as a shaped grip that is usually attached to a climbing wall so

climbers can grab or step on it. On most walls, climbing holds are

arranged in paths, called routes, by specially trained route

setters. Climbing holds come in a large array of sizes and shapes to

provide different levels of challenge to a climber. Climbing holds

are either bolted to a wall via hex-head bolts and existing t-nuts

or they are screwed on with several small screws.

The

Anderson Climbing Holds

The first bolt on holds were designed

or devised by Leonard C. Anderson and first used in the

climbing wall at Royal Belfast Academical Institution in the late

1960’s.

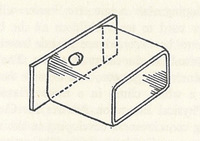

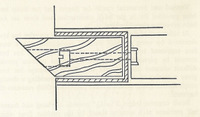

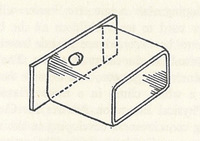

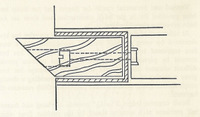

The lack of flexibility that the

climbing walls offered at the time was a recognised problem.

Anderson’s solution was metal boxes with a nut at the back.

These were cemented or otherwise secured into a brick wall. Anderson

devised a matrix for their layout. They were fitted at 2’

vertical intervals and 2’ 6” horizontally. Into the

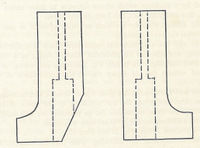

housing were fitted a hardwood (Beech) block that could be recessed,

fitted flush with the wall or shaped and fitted to project from the

wall.

The symmetrical appearance of the hold placements was aesthetically

pleasing and is still used to day though the hold density is much

greater. It also solved the age old problem of having projecting

holds into a multi use sports facility. Insert holds could be fitted

up to an 8’ height so as not to cause a hazard when the hall

was used for basketball or five a side. |

|

|

|

|

|

|

|

|

|

|

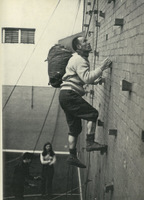

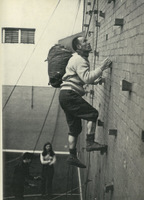

West Common Sports Centre,

Scunthorpe (photo R Holmes, BMC) |

|

|

|

|

|

Cast Resin

Holds

These have become the industry standard and is what we know today

as a bolt on hold.

Francois Savigny was an industrial

engineer and rock climber, founded Entre-Prises in 1985 with help

from Petzl Climbing Equipment. The first products to be sold were a

selection of modular bolt-on holds made from resinous concrete and

these were the first commercially marketed cast resin bolt-on

climbing holds. The importance of the bolt on climbing hold cannot

be underestimated. As for the first time climbs or routes could be

created and changed simply by screwing a resin hold on a wall using

a standard engineering bolt and fixing. It created a revolution in

the design of climbing walls from the heavy cast concrete structures

to the lightweight plywood or fibreglass structures we are familiar

with. It is interesting to note that in 1988 the BMC (British

Mountaineering Council) published the first of it’s Climbing

Wall Manuals, (Full tittle - Development, Design and Management of

Climbing Walls - A Technical Information Manual for Architects,

Leisure Mangers and Climbers) there is not one mention of cast bolt

on holds, but concentrated on setting rocks into brick walls or

precast concrete blocks with rocks set in them and large cast

reinforced concrete features. It was produced on the cusp of the new

age of climbing wall development. It was like Punk Rock wiping the

floor of the Progressive Rock, or to put it into context Grunge

taking over from Stadium Rock.

Early

Bolt On Hold Manufacturers

Metolius claim to have been making holds since 1986. Canyon

Holds, another French company were probably the next company to

start manufacturing cast resin holds. Rockworks were the

first British manufacturer of cast resin holds in 1988 and Nicros

in USA, have also been making holds since 1988. Today 100's of

manufacturers World wide produce climbing holds.

How

are Bolt on Holds Made

The bolt on hold has changed little in the intervening years since

it was invented in 1985. There are certainly more of them, more

colours and the range of sizes is now vast. First the shape is

carved often from a closed cell polyurethane foam. The texture of

holds is defined by the grade of foam used, and it is similar to

Oasis foam (florists foam), but being closed cell it doesn't absorb

water. Once carved the holes for the fixings are made into the foam

former. A silicone rubber mould is made around the foam former by

setting the hold in a box with removable sides. The rubber is poured

over and left to set. With the sides removed the silicone rubber can

also be removed. The flexibility of the silicone allows the foam

former to be removed. The silicone is excellent at picking out all

the faint features of the foam. With the silicone rubber turned

upside down it becomes a simple mould. The polyester resin mixture

is poured into it an allowed to set. Once set the flexibility of the

silicone allows even quite complex shapes to be pulled from it.

During the setting process the polyester resin produces a exothermic

reaction. This heating of the silicone will eventually cause it to

harden and become less flexible.

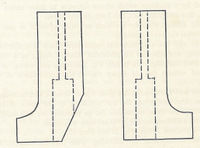

In the late 1980’s there was no standard fixing design each

manufacturer used what they thought practical Entreprise used a M10

bolt fixing whilst Canyon used a M12 fixing and also produced glue

on holds. A least one manufacturer used M8 bolts. All holds were

produced with an inset flat area to take either a cap head or button

head bolt. The flat area was often reinforced by casting into the

hold a flat washer. By the early 1990’s the industry had

settled on an M10 fixing bolt. Many manufacturers changed to a

countersunk fixing as they identified the in-situ washer as a

weakness as many holds broke along this. The countersunk fitting

allowed the bolt a greater surface area contact, and therefore

required less torque in tightening to stop the hold form turning or

spinning.

Polyester

Resin Holds

Most companies that manufacture bolt or screw on holds, climbing

holds, still use a polyester resin mixture the type used by many

fibreglass companies.

In the Entreprise (UK) brochure, 2011/2012,

about 90% of their range is in Polyester resin. Entreprise USA (March

2011) advertises approximately 350 PU holds of their 1000+ hold

range. HRT (Walltopia) appear to have close to a 50/50 split with

Polyester holds to polyurethane holds. Nicros use corn/soya oil

in their holds they do not say what percentage, and presumably it

is a polyurethane resin. Bendcrete claim it is the cost of remoulding

its holds as the main reason they have not marketed polyurethane

holds.

The resin mixtures are good at taking

the form in the silicon moulds and therefore can create detailed

textures and with variety of silica based fillers can be very

durable and less prone to polishing than with resin alone. The

longevity of the holds depends as much on the fillers as the type of

resin and pigments used and the environmental conditions it is

subjected. As well as, how the hold is treated. Many holds on

climbing walls have been known to be still in use after 20 years or

more. Heavily used holds in a climbing centre may have lost the

texture after only a year and therefore replaced even though the

structural integrity of the hold is not compromised. Outside they

are also subjected to heat and cold. UV degradation of many general

purpose resin may mean the holds only last a few years before they

become brittle. The colour also fades very quickly outside when

inferior pigments are used, so as the holds age they become more and

more brittle until they eventually crack.

Because polyester resin holds are not

flexible, they will often crack suddenly if they are being tightened

down on a wall that is not completely flat, ask anyone that has

route set on curved resin walls. A final problem is the weight of

resin climbing holds. As hold sizes have grown and grown, in many

cases the resin aggregate composite has become an impractical

material to use. Even when the hold is hollow-backed, resin

aggregate is still quite a heavy material to be carried up the wall

in a bucket. We say Polyester as a generic term to refer to both

isothalic, orthothalic polyester and the slightly different

vinylester. The reason polyester holds are so popular is because it

is cheap, usually less than half the price of Polyurethane resins.

So despite all the health and safety hazards encountered in

production it remained the industry standard for 25 years.

Primary Health Concerns in Manufacture

Eyes - Can cause severe irritation,

redness, tearing, blurred vision.

Skin - Prolonged or repeated contact

can cause moderate irritation, defatting, dermatitis.

Inhalation - Excessive inhalation of

vapors can cause nasal irritation, dizziness, weakness, fatigue,

nausea, headache, possible unconsciousness, and even asphyxiation.

Swallowing - Can cause

gastrointestinal irritation, nausea, vomiting, diarrhea. Aspiration

of material into the lungs can cause chemical pneumonitis

Chronic: Repeated overexposure may cause central nervous system

damage, kidney damage, liver abnormalities, lung damage, cardiac

abnormalities, reproductive organ damage, skin sensitization and

dermatitis.

However because polyester resins

contain about 50% Styrene it is classed as type II carcinogen,

because of studies on mice showed a significant increase of lung

cancers. The Styrene Information and Research Center (SIRC) reported

no link between styrene exposure and an increased incidence of

cancer has been found collectively in eight studies of workers in

the reinforced plastics and composites industries prior to 1992.

Primary Safety Concerns

Highly flammable and contact with

strong alkalies, strong mineral acids, and oxidizing agents. Methyl

ethyl ketone peroxide (MEKP) is used as the catalyst to harden the

polyester resin. MEKP is an organic peroxide and extremely dangerous

solvent. It is a very volatile liquid that quickly fills the air

with toxic fumes that can cause permanent damage to the central

nervous system. A similar organic peroxide was used as a torpedo and

rocket propellant. A simple fact that it provides it’s own

oxygen to burn and in doing so releases more oxygen to feed more

fuel. In contact with copper it will expand hundreds of times at a

rate of 5.2km/s. In a confined space this is effectively and

explosion. For further reading see the Russian submarine

The

Kursk or the

2006

transatlantic aircraft plot

Polyurethane

Resin Holds

Currently most commercial hold manufacturers are moving to holds

made from polyurethane or polyurethane mixtures. Polyester resin

holds though still dominate the market. Polyurethane is not new to

climbing as those of us who lived through it will bear witness to.

When cast bolt on holds were first invented many climbers were

wearing it, but they new it as lycra, elastane or spandex. In

manufacturers literature they often refer to them as PU holds. They

are sometimes wrongly refered to as urethane holds. Urethane is

Ethyl Carbamate and polyurethanes neither contain nor are produced

from ethyl carbamate. Polyurethanes, especially those made using

aromatic isocyanates, contain chromophores which interact with light

causing deterioration, therfore may not be suitable for long term

outdoor use.

Polyurethane is a better product for

holds because it is lighter, more flexible, and less prone to

chipping and breakage than resin or natural materials. More

importantly there are less of the health and safety effects

associated with polyester resins. Like other resins, polyurethane

mixtures can vary, and different mixtures have varying strengths.

The manufacturing principle is the same as polyester resin. Measure

the liquid isocyanate and resin blend at a specified ratio, mix them

together with any fillers until a homogeneous blend is obtained,

dispense the reacting liquid into a mold, wait until it cures, then

demold the finished hold.

Primary Health Concerns

R36 Irritating to eyes. R37 Irritating to respiratory system. R65

Harmful may cause lung damage if swallowed

Primary Safety Concerns

Flammable

Future

Development - Corn (Maize) and Soya based Resins

In February 2009 – Nicros owner and President Nate Postma

announced that, Nicros, is proud to be the first climbing handhold

manufacturer to introduce the use of an environmentally-conscious,

Corn/Soy-Based resin into its Super-Mix recipe. This resin, made

from renewable resources, is now used in the production of all

Nicros and PM Climbing Systems training tools and handholds. Postma

said, “This new resin is an important step forward in

supporting the effort to reduce petroleum consumption.”

These are known as natural oil

polyols, also known as NOPs or biopolyols, are derived from

vegetable oils by several different techniques, and the primary use

for these materials is in the production of polyurethanes. Since

2004 the biggest investor in these has been Ford who have used

polyurethane foam derived from soya oil in it's car seats since

2008. We have yet to see any

significant change in the marketing of bolt on holds in favour of

polyols, but it is certain that major manufacturers of polyurethane

will be introducing it into their resins.

|

|

|

|

|

Page

Acknowledgements and References:

Me

Wikipedia -

Polyurethane

BMC

General Acknowledgements:

|

|